Our client, a consumer electronics retailer, was facing the need of reviewing its supply chain to reduce the distribution costs of large formats (e.g., refrigerators, washing machines) from its central warehouse to the customers’ home. We were invited to tackle this operations strategy problem aiming to minimize transportation and structure costs without jeopardizing customer service level.

The distribution was at that time outsourced to a specialized 3PL. Therefore, the approach should not only be able to come up with the best network configuration but also to make additional recommendations to revise logistic rates.

This challenge was tackled using a two-step optimization approach. Firstly, given the intended number of cross-docking hubs, the best locations to set up the operation were found. Secondly, for each configuration, operational costs were calculated using a state of the art routing algorithm and the optimal number of hubs was determined.

A simulator was then developed to assess the feasibility of the solutions since there were other operational details to be considered, as the variability in traveling or installation times.

This validation was essential to ensure the intended service level.

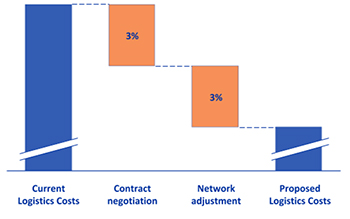

The optimization of the large formats distribution network allowed the retailer to reduce its operational costs by 3%. Moreover, a set of negotiation recommendations was prepared which could mean up to 3% of extra savings.

Finally, the methodology allowed the identification and quantification of opportunities to improve customer value proposition (e.g. same day delivery).