Each warehouse is unique and designed to meet the company’s specific needs. Hence, there is no one-size-fits-all approach to warehouse design. The challenge is to overcome this pain point by developing a product that could easily be adjusted into all these tailor-made layouts.

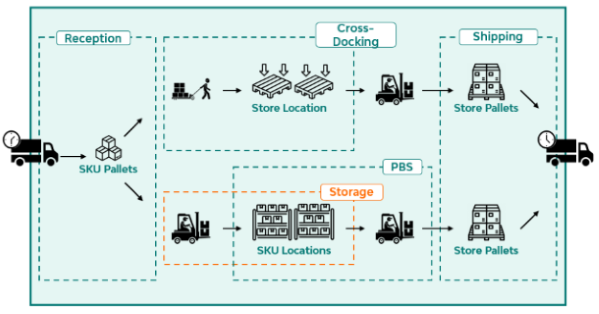

Despite their uniqueness, all warehouses comprise three major zones: inbound, storage/picking, and outbound, with differences in configuration and placement along the shop floor.

The inbound area is where suppliers deliver the ordered products. The pallets will follow different paths according to the picking policy: cross-docking or Picking by Store (PBS). In cross-docking, pickers start with a full pallet and deliver products to store-specific locations along a predetermined route. PBS involves collecting items for a store in one go, with locations representing SKUs instead of stores. For both picking policies, when a store pallet reaches its maximum, it is moved onto the marshaling area, where store pallets are staged before shipping.

The focal question of this case study is how to dynamically arrange the cross-docking zone to minimize picking operation time based on the variable demand expected. This involves optimizing store locations in the picking area to reduce the total route distance. However, blindly reducing the distance can lead to clustering all high-order stores, causing congestion. Therefore, one must consider this tradeoff between distance and congestion to enhance warehouse efficiency.

A hybrid approach combining simulation and optimization was developed. The modeling strategy can be swiftly adapted to each functional block of the warehouse, with the cross-docking picking area being the focus in this case. The hierarchical structure of the models used is sequential: Simulation-Optimization-Simulation (SOS).

1. S – High-level Simulation: Deploy scenario testing within the simulated functional block of the warehouse. Within this module, it is possible to quickly simulate multiple configurations regarding factors such as internal layout design, routing constraints, and storage assortment strategies.

2. O – Optimization: The goal of this module is to optimize the allocation of stores to warehouse positions, ensuring the best balance between total traveled distance and picking task congestion.

3. S – Discrete Event Simulation: This model aims to test the robustness of the generated solutions, validating the high-level simulation model. In this step, the warehouse at hand is emulated from an AutoCAD file with the precise measurements of the picking area using a commercial simulation software. This approach ensures a more accurate and granular representation of the cross-docking block, although it is much more computationally heavy and time-consuming.

The proposed methodology was able to define the optimized store location in a warehouse, handling different layouts, allocation cycles, and restrictions. The methodology was analyzed in the warehouse of a large retailer, testing for different allocation periods, layout configurations, and operational constraints. It was possible to effectively reduce the distance traveled by pickers by 13% for a daily reallocation, which could increase to 18% with a more precise capability of predicting the next day’s pallets.

The considered warehouse operates in two shifts, and not all stores receive deliveries daily. After the end of the second shift, there is no reallocation of the stores’ pallets that are still in preparation. Therefore, it must be possible to consider that the stores not scheduled for delivery on a specific day maintain their position in the layout for the following day. Additionally, the positions in the layout have different pallet capacities (1 to 7 pallets). Therefore, a store can only be assigned to a position with enough buffer capacity to store all its pallets between deliveries. Considering these conditions in the model, it was still possible to reduce the traveled distance by 8%.

It is also important to note that the current warehouse allocation has been finely refined over time by empirical experience. Therefore, greater distance reductions could be achieved in warehouses with less empirical optimization.

For the proposed solutions, congestion remained constant, and comparable to that in the original layout. Consequently, the reduction in traveled distance directly impacts operational time, greatly increasing the operation efficiency.

By: Vasco Patarata , Diogo Bento , Catarina Borges