In the dynamic landscape of modern manufacturing, maintaining a competitive edge requires a departure from conventional methods. This entails an unwavering commitment to enhancing sales performance while concurrently streamlining operational costs. While operational teams strive for optimal efficiency in utilizing an organization’s capital assets and maximizing added value, commercial teams direct their efforts towards revenue maximization. They prioritize meeting the demands of willing-to-pay customers by offering short lead times, a diverse product portfolio, and capitalizing on high-revenue products.

Undesirably, many organizations encounter common challenges that result in inefficiencies and missed opportunities. The various factors contributing to the entropy that hampers organizational performance can be effectively addressed at different planning levels, with a particular emphasis on tactical planning. One common axis of tactical planning is portfolio strategy planning. This entails enterprises deciding which products to produce by order, engaging in lower inventory and raw material costs, and determining which products to keep in stock to facilitate faster lead times and more efficient production processes.

Effectively navigating this paradigm is compounded by challenges inherent to every manufacturing organization.

LTPlabs oughts to provide partnering organizations with advanced analytical solutions that gives them a competitive edge, such as their tactical planning procedures. By substantiating these decisions through the use of decision support systems founded on cutting-edge analytical methodologies, businesses can enhance their efficiency, anticipate customer behaviour more accurately, and achieve superior strategic and tactical alignment.

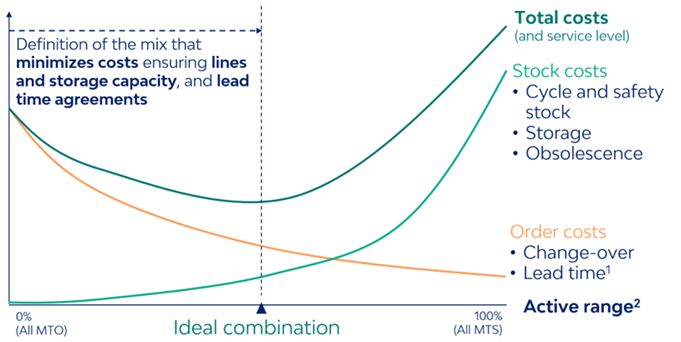

In the realm of tactical planning, specifically portfolio strategy optimization, enterprises with extensive portfolios face the challenge of deciding which products to produce for stock and which to produce on-demand. This dilemma involves a critical trade-off between producing more efficiently in larger quantities or less efficiently in smaller quantities, significantly impacting the organization’s cost structure.

Producing for stock requires sizing the inventory to meet desired service levels, ensuring quick fulfilment of customer demand. Despite the advantage of scheduling productions and optimizing production lots, this approach necessitates producing more to accommodate the unpredictability of customer demand, thus incurring in greater inventory and holding costs.

Conversely, triggering production based on orders eliminates the uncertainty of demand prediction, leading to reduced production quantities and lower inventory costs. However, this approach hampers the ability to scale production, resulting in more frequent and less efficient productions, increased downtime, and congestion.

Moreover, more intricate production processes including intermediate goods add a further layer of complexity for decision makers. They must determine whether to decouple the production of intermediate goods from the subsequent finished product strategy.

Opting for upstreaming the inventory point offers advantages akin to scaling production for intermediate goods and producing finished goods on demand.

This approach maximizes efficiency in utilizing upstream resources while ensuring expedited delivery.

Trade-off between Making to Order (MTO) and Making to Stock (MTS)

Therefore, achieving and maintaining this often-tenuous equilibrium is an important step for organizations aiming to provide competitive services while simultaneously keeping costs in check. Advanced analytical tools leverage data in that sense and establish a common ground among decision-makers within an organization, reshaping management practices. Understanding the ripple effects of decisions, across the entire organization, holds the key to unlocking unprecedented value.

The integration of advanced analytical methodologies can face scepticism from decision-makers. LTPlabs assumes the role of a facilitator and mediator, bridging diverse stakeholders and objectives.

We facilitate the adoption and understanding of developed tools, ensuring close validation with commercial, operations, and IT teams.

Our commitment extends to providing thorough training to key stakeholders for autonomous model utilization, extracting maximum value. Additionally, we develop comprehensive guides, empowering teams in the proper utilization and maintenance of both the model and data infrastructure.

In conclusion, LTPlabs stands as a steadfast ally to organizations dedicated to ushering in an era of data-driven decision-making. It empowers businesses to improve their tactical planning, harmonize conflicting expectations and tap into the untapped potential of information across the entire value chain. This revolutionary solution underscores how forward-thinking enterprises can overhaul their strategies, maintain competitiveness, and pave the way for a brighter, remarkably efficient future.

By: Rodrigo Castro , Daniel Pereira