While supply chain network design has been around for some time, organizations are now starting to acknowledge that the supply chain structure plays a too important role to be left over to chance, being able to differentiate them from the competition.

Moreover, supply chains have become more complex and global due to the growing business environment volatility, as well as by virtue of the set of sophisticated technologies that have been reaching the market (and which allow the gathering of data from many different sources). So how can companies deal with these challenges and design a profitable network?

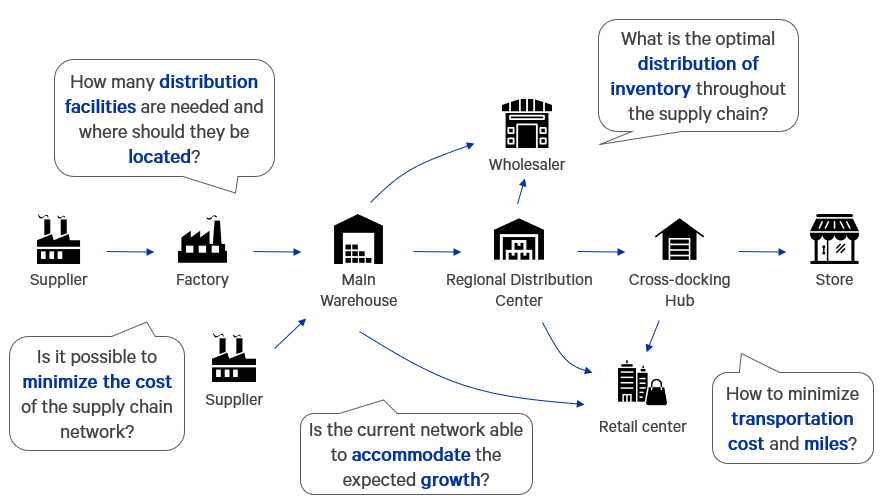

A supply chain network is defined by all intervenients between the products’ origin and the final customer. The facilities’ location and their flows are of utmost importance, accounting for the majority of the supply chain associated costs and defining the service level provided to the customers.

The main goal of network design is to balance these two levers and align them towards the companies’ strategic positioning, supported by robust analytical modeling.

Trade-off between physical locations and transportation costs

From another perspective, the complexity of the supply chain is directly linked to both internal and external factors that coexist around the business environment. The supply chain should be able not only to adjust to externalities such as changes in demand patterns or government regulations but also to accommodate the companies’ growth plans or new revenue streams (new products and/or new markets).

In this insight, we explore two practical applications of network design that tackle distinct viewpoints on the topic: customer orientation and efficiency orientation.

Our client, a consumer electronics retailer, was facing the need of reviewing its supply chain to reduce the distribution costs. The challenge was tackled using a two-step optimization approach. Firstly, given the intended number of cross-docking hubs, the best locations to set up the operation were found. Secondly, for each configuration, operational costs were calculated using a state-of-the-art routing algorithm and the optimal number of hubs was determined.

A simulator was then developed to assess the feasibility of the solutions since there were other operational details to be considered, such as the variability in traveling or installation times. This validation was essential to ensure the intended service level.

The optimization of the distribution network allowed the retailer to reduce its operational costs by 3%.

The online fashion retailer aimed to assess all the impacts of opening a new warehouse with a focus on the client experience (i.e., delivery lead time, predictability) while not jeopardizing the operational distribution efficiency (i.e., shipping fees, warehousing costs).

The first step of the methodology consisted on the development of a customized predictive model with the goal of identifying how the experience may impact client retention.

Then a supply chain analytical model was applied to forecast shipping fees, lead times, and anticipate warehousing costs.

Several scenarios were outlined and the best location for the new warehouse was found.

This study allowed us to conclude that the opening of the new unit would increase the margin by 8%.

As we can learn from the previous examples, irrespectively of the initial motivation behind the supply chain optimization, any network design problem needs to balance the client experience or service level against the operational efficiency.

From a methodological perspective, an effective network design requires:

By: Daniel Pereira , Diogo Miranda